Warszawa 29-06-2024

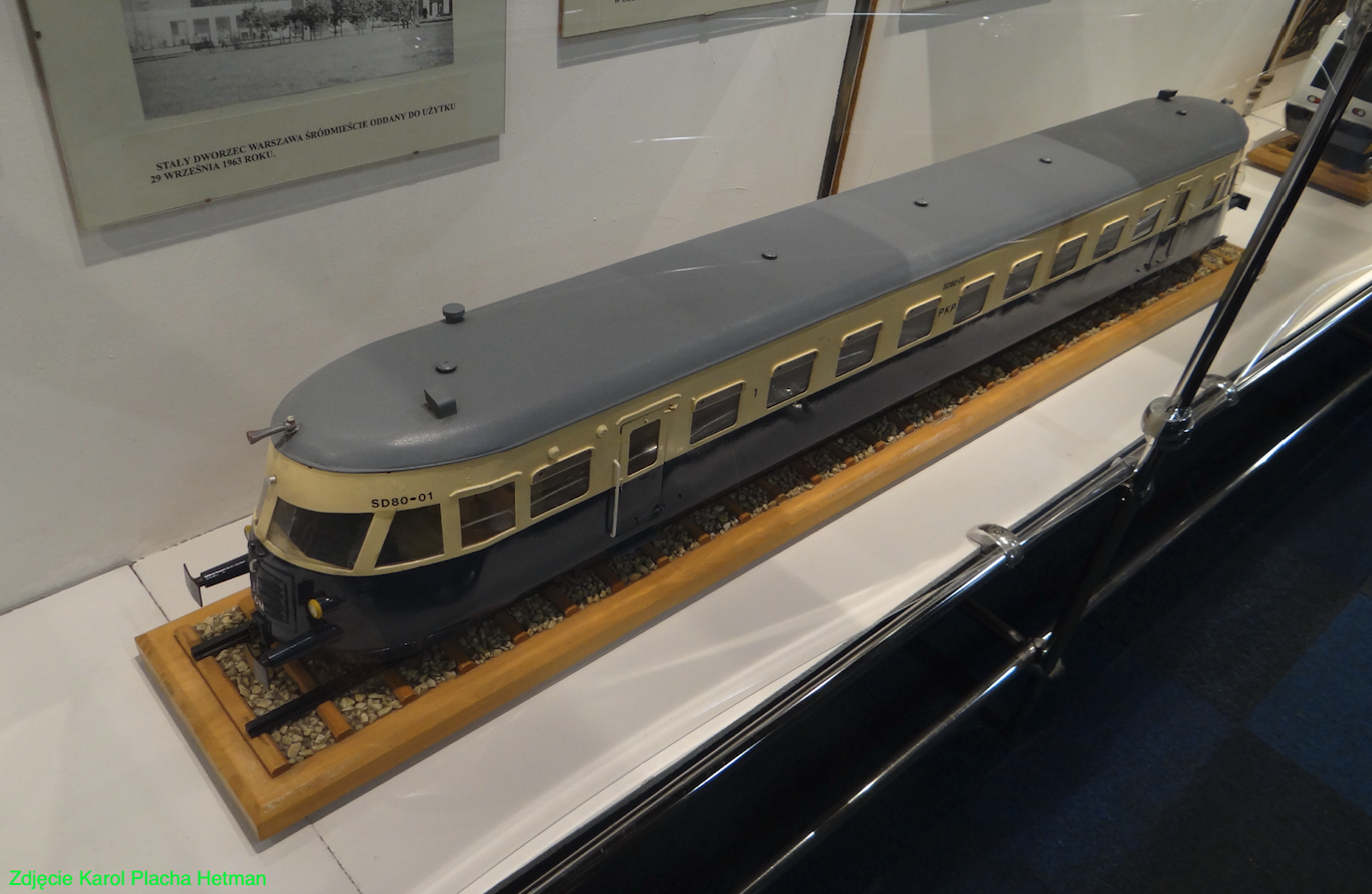

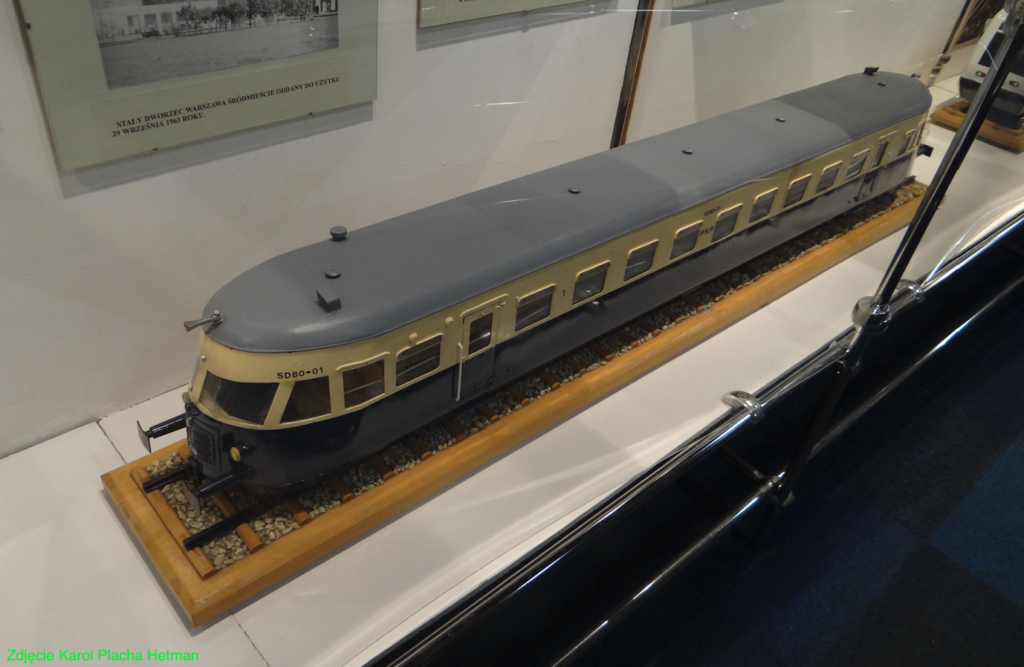

History of the SD80 series of motor wagons.

Until the Second World War, motor wagons were popular and their propulsion systems varied widely. The wagons were powered by steam engines, electric motors powered by batteries and internal combustion engines, which were most often powered by petrol. Polish industry also produced wagons of this type, and the most popular was the Luxtorpeda, made by FABLOK.

In 1948, PKP stocked 45 railcars, mostly of Germanic manufacture, which came from the railways in the recovered lands. However, only 8 were in service. The rest were severely damaged. Shortly after the war, these wagons made a percentage of 10 times fewer runs than in 30 years. The main reason was the high failure rate of these wagons. The lack of spare parts meant that many motor wagons were converted to semi-trailer wagons. In addition, the PKP needed steam locomotives and coal wagons more. In addition, there were no manufacturers of powerful internal combustion engines and traction transmissions in Poland. In addition, there was a gradual isolation of Poland from Western Europe.

In 1949, the PKP bought three diesel railcars of the SD80 series. The manufacturer of these wagons was the Italian company FIAT – Officine Meccaniche in Milan. This was the only PKP purchase of this type in Western Europe. Poland decided to electrify its main railway routes and produce heavy steam locomotives. Diesel traction had to wait a few years in Poland.

In Italy, the factory’s vehicles carried the designation Aln772. In Poland, the SD80 diesel railcars were originally numbered 090 051, 090 52, 090 053 and the MsBx series. After the change of classes in 1956, they were designated MsAx, and in 1959, only the SD80 series. The purpose of purchasing the SD80 wagons was also to develop a Polish engine car and produce it at the HCP works. However, it turned out that suitable engines and suitable traction transmissions were not manufactured in Poland. These components would have had to be purchased abroad, which was uneconomical. The Italians made changes to the wagon’s design for the PKP. The driver’s seat was moved from the left side to the right side as used in Poland, and a boiler was introduced.

Three SD80 coaches arrived in Poland in 1951. Seat reservations were introduced in the wagons. In 1953, the wagons began operating on the route Warsaw – Gdańsk – Gdynia. The vehicles were also sent on the Warsaw – Katowice – Gliwice route. In 1959, a connection between Warsaw and Bydgoszcz was launched. In the summer season, the carriages as the “Blue Wave” were sent on the route Warsaw – Szczecin – Swinoujscie. The carriages ran at speeds of over 100 km/h. Speeds of 130 km/h were recorded. It was the fastest train in Poland at the time.

In 1962, the SD80 coaches were directed to operate the “Lech” express on the Warsaw-Poznań-Warsaw route, with a scheduled speed of 90 km/h. In 1963, all three vehicles were diverted from Warsaw East to the motor carriage depot at Gdańsk. The SD80-series coaches were in passenger service until 1967, when they were converted to SR70 inspection coaches. The wagons were finally withdrawn from service in 1974. The main reason for this was the electrification of the major rail routes and the introduction of electric locomotives with a maximum speed of 125 km/h, along with the wagons.

The SD80-02 series engine car survived into the 21st century as an exhibit of the Railway Museum in Warsaw. Unfortunately, it stood on a side track and deteriorated. In addition, it fell prey to thieves and vandals. In December 2009, the wagon was pulled onto the repair track. In 2010, the wagon was repainted with anti-corrosion paint, but there were no funds to fully maintain it. It was again placed on a side track. In 2013, the carriage was pulled off the bogies, which were placed next to it. When the reconstruction of Warsaw Central station began, the carriage was taken to an unknown location.

The design of the SD80 wagon.

The wagon was equipped with two internal combustion engines, located at both ends of the vehicle. Each engine drives only one other axle of the carriage. But the engines are designed to work together. Axle arrangement (1A)'(A1)’. In addition, it was possible to combine two carriages into one train, controlled from one station.

The interior of the SD80 wagon was divided into several sections. At each end of the wagon was a compartment housing the internal combustion engine and driver’s cab. Further on was the toilet and the heating boiler compartment. Further on was the entrance vestibule. The passenger cabin was single-space with 72 seats on soft couches. Further on was the rear entrance vestibule, the service compartment and the rear driver’s cab. Luggage space was located under the seats and on shelves mounted above the windows along the carriage. The floor of the passenger compartment was made of aluminium corrugated sheet metal, covered with cork panels and lined with linoleum. In the toilet and heating compartment, the floor was made of stainless steel.

The wagon body structure is made of steel and wood. The front of the wagons received an aerodynamic shape, headlights, bumpers and coupling. The interior of the wagon, walls and ceiling, was lined with lacquered plywood. Glass wool was placed under the plywood. The outer cladding of the wagon was made of 2 mm thick steel sheet and the roof was covered with 1.5 mm thick steel sheet. The glass in the windows was made of toughened glass. The windows were opened with a crank located under the window. In the driver’s cabs, the windows were made of 8 mm thick glass. The side windows in the driver’s cabs are opened, using a crank, by lowering down. The carriage has four entrance doors that open outwards. The doors have an opening window.

The 24-volt electrical system is powered by two alternators and batteries. The heating boiler is automatic and ran on the same fuel as the combustion engines. The heated air, via a fan, was ducted to the passenger area. With the boiler off, the air supply ventilated the interior of the vehicle.

T-T data of the SD80 railcar:

Axle arrangement (1A)'(A1)’. Unladen weight 25 000 kg. Service weight 34,200 kg. Length with buffers 24.560 m. Width 3.16 m. Height 3.564 m. Bogie pivot spacing 16.00 m. Bogie wheel base 3.05 m. Outer axle spacing 19.00 m. Wheel diameter 0.90 m. Engine type Saurer OM-BXD, two units. Engine rated power 2 x 110 kW. Hydraulic transmission type Lysholm-Smith DF 1.15. Fuel tank capacity 550 litres. 24 V electrical system, used for lighting. Heating taken from the boiler system. Forced ventilation. Design speed 130 km/h. Seating capacity 72.

Written by Karol Placha Hetman